Best Barrel Hand Trucks for Easy Moving and Transporting Heavy Loads

In the industry of material handling, the significance of the right tools cannot be overstated, particularly when it comes to transporting heavy loads. Among these tools, the barrel hand truck has emerged as a vital asset for both businesses and individuals dealing with bulky items. According to a recent report by the Material Handling Industry of America (MHIA), effective use of appropriate hand trucks can lead to a 25% increase in operational efficiency in warehouse environments. This underscores the importance of choosing the best barrel hand truck to simplify the moving process.

Industry expert John Smith, a well-respected figure in the field of logistics, emphasizes, "The right barrel hand truck not only alleviates physical strain but also enhances productivity by allowing for smoother transport of heavy barrels." These trucks are designed specifically to handle the unique challenges posed by cylindrical loads, ensuring stability and safety throughout the transportation process. As we delve into the various options available, it's essential to understand the specific features that make a barrel hand truck optimal for diverse applications. The following sections will highlight the best choices in the market, equipping you with the knowledge needed to make an informed decision for your moving and transporting needs.

Best Barrel Hand Trucks: Overview of Features and Benefits

When it comes to moving and transporting heavy loads, barrel hand trucks are unbeatable tools that combine efficiency with ergonomic design. According to industry reports, the global hand truck market is projected to grow at a CAGR of 5% from 2021 to 2027, highlighting the increasing demand for this essential equipment in warehouses and manufacturing facilities. Barrel hand trucks are specifically designed to handle cylindrical loads, which greatly enhances their utility in industries dealing with barrels, drums, and other round containers.

Featuring robust construction often made from steel or high-strength aluminum, the best barrel hand trucks afford stability and durability. Many models come equipped with pneumatic or solid rubber wheels, providing smooth maneuverability over uneven surfaces. Additionally, ergonomic handles and innovative designs reduce the risk of strain and injury during operation, reflecting a growing focus on workplace safety. Reports indicate that ergonomic equipment can decrease work-related injuries by up to 30%, underscoring the importance of selecting the right tools for heavy-duty tasks. With features that prioritize both functionality and safety, investing in a quality barrel hand truck is essential for efficient heavy load management.

Best Barrel Hand Trucks for Easy Moving and Transporting Heavy Loads

| Model | Load Capacity (lbs) | Weight (lbs) | Wheel Type | Material | Price ($) |

|---|---|---|---|---|---|

| Heavy Duty Barrel Truck | 800 | 50 | Pneumatic | Steel | 199.99 |

| Compact Barrel Dolly | 600 | 30 | Solid Rubber | Aluminum | 129.99 |

| Heavy-Duty Drum Cart | 1000 | 55 | Polyurethane | Steel | 249.99 |

| Ergonomic Barrel Mover | 500 | 28 | Swivel | Composite | 159.99 |

| Drum Handling Truck | 750 | 48 | Solid Rubber | Steel | 219.99 |

Key Features to Look for in Barrel Hand Trucks for Heavy Loads

When selecting an ideal barrel hand truck for moving heavy loads, several key features come into play. First and foremost, the weight capacity is paramount. According to industry standards, many barrel hand trucks support loads ranging from 600 to 1,500 pounds, making it essential to choose a model that safely accommodates your specific transportation needs. Additionally, opting for a hand truck with a reinforced frame enhances stability and durability, crucial for frequent use in warehouses or construction sites.

Another critical aspect to consider is the wheel design. Reports from the Material Handling Industry (MHI) indicate that larger, pneumatic wheels significantly improve maneuverability and reduce strain on the user when navigating over uneven surfaces. Furthermore, a truck with a swivel front wheel enables easier turns, making it more efficient in tight spaces. Ergonomic handles also contribute to user comfort; the right grip can reduce fatigue, particularly during extended periods of use, thus improving overall productivity. By prioritizing these features, users can ensure they invest in a barrel hand truck that effectively meets their heavy-load transportation requirements.

Best Barrel Hand Trucks for Easy Moving and Transporting Heavy Loads

This chart illustrates the key features of top barrel hand trucks, highlighting their weight capacity, wheel size, price, and material quality rating, providing a clear comparison for users looking for the best options for heavy load transport.

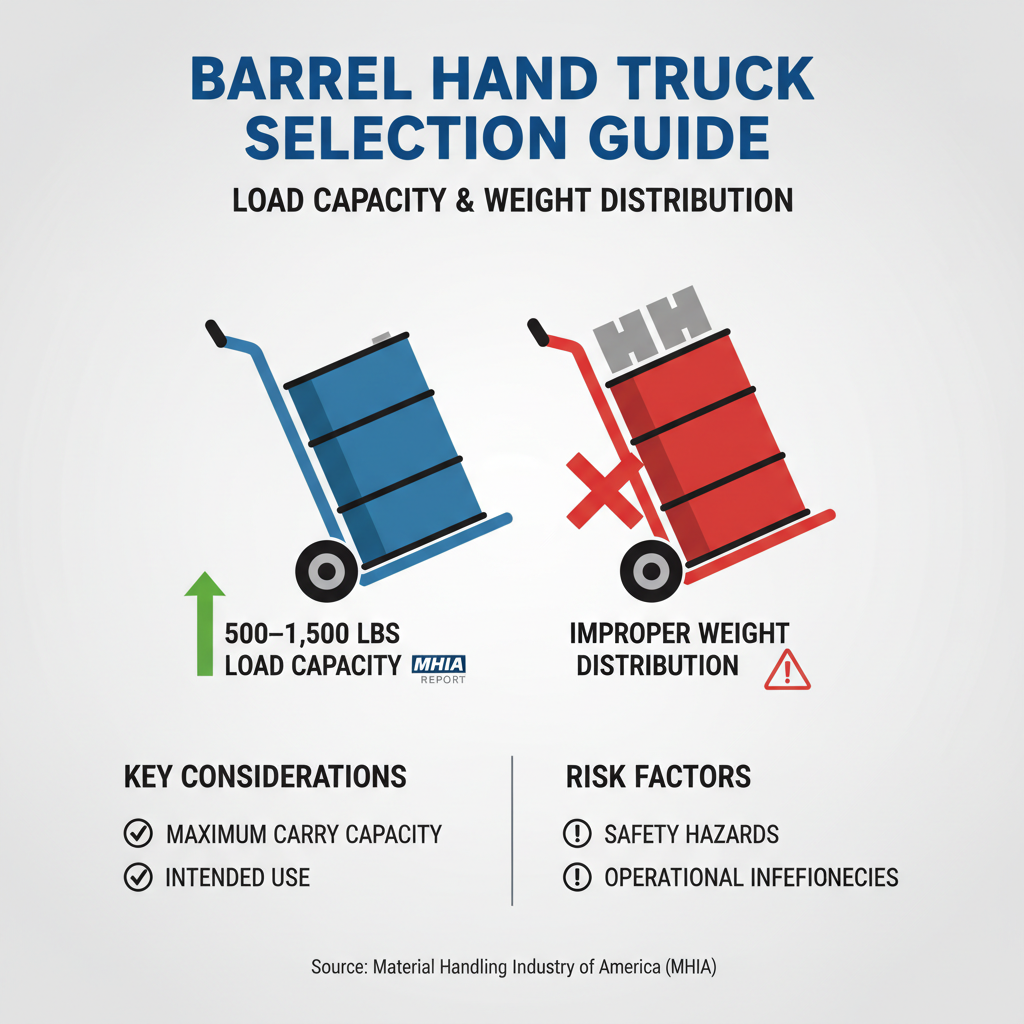

Industry Standards: Load Capacity and Weight Distribution in Hand Trucks

When selecting barrel hand trucks, understanding load capacity and weight distribution is paramount. According to a report by the Material Handling Industry of America (MHIA), the load capacity of hand trucks on the market typically ranges from 500 to 1,500 pounds. Selecting the right hand truck requires awareness of both the maximum weight it can carry and the intended use, as improper weight distribution can pose safety risks and lead to operational inefficiencies.

Furthermore, the importance of weight distribution cannot be overstated. A study published by the American National Standards Institute (ANSI) emphasizes that uneven weight distribution can result in tipping or instability, especially when navigating inclines or uneven surfaces. Hand trucks designed with a wider base or specialized design features can enhance stability, allowing for easier maneuvering of heavy loads.

For example, barrel hand trucks with a 60-degree angle on the toe plate often exhibit better load handling abilities, reducing the likelihood of accidents in industrial settings. Therefore, it is critical to consider both load capacity and weight distribution when investing in a hand truck for transporting heavy barrels or other loads.

Comparative Analysis: Top Brands and Models in the Barrel Hand Truck Market

When it comes to transporting heavy barrels and loads, selecting the right hand truck can make all the difference. In the competitive market of barrel hand trucks, top brands like Magliner, Harper, and Milwaukee stand out for their innovative designs and functionality.

Magliner offers lightweight aluminum models that are not only easy to maneuver but also exceptionally durable, while Harper's hand trucks are known for their heavy-duty construction, providing an excellent choice for industrial settings. Milwaukee, on the other hand, features ergonomic designs that enhance user comfort during long periods of use, making them a favorite among those who require frequent heavy lifting.

A comparative analysis of these brands reveals distinct advantages in their design and usability. For instance, Magliner's models typically include features such as

- adjustable straps

- larger wheels

Maintenance Tips for Enhancing Durability of Barrel Hand Trucks

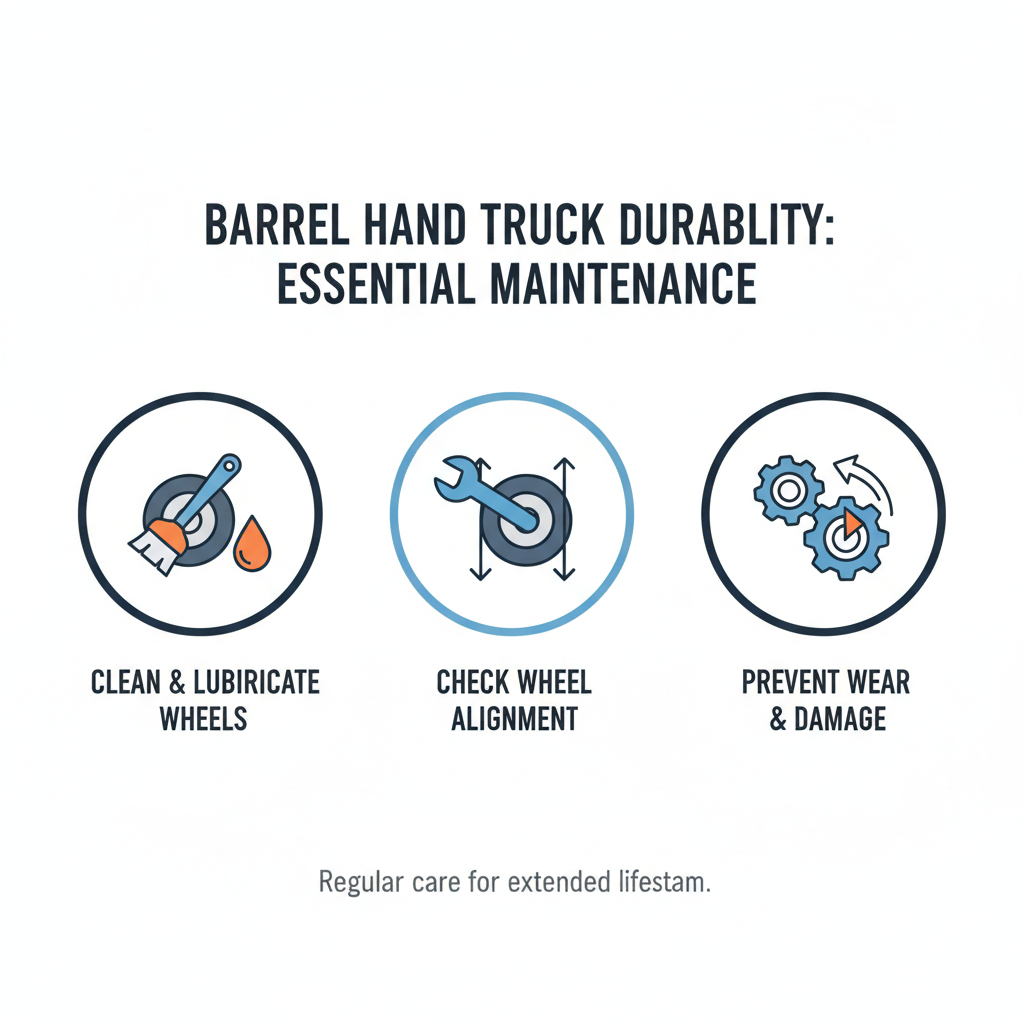

To enhance the durability of barrel hand trucks, regular maintenance is essential. First and foremost, ensure that the wheels are kept clean and well-lubricated. Debris and dirt can cause excessive wear and tear on the moving parts, leading to decreased efficiency and potential damage. Periodically check the wheel alignment as well; misalignment can place unnecessary strain on the hand truck, shortening its lifespan.

Additionally, inspect the frame for any signs of rust or corrosion, especially if the hand truck is used in outdoor environments. Applying a protective coat of paint or rust-resistant spray can help shield the metal from the elements. It’s important to avoid overloading the hand truck beyond its weight capacity, as this can lead to structural damage. Regularly tightening bolts and screws ensures stability and safety during transportation, ensuring that your investment remains in top condition for many years to come.

Related Posts

-

7 Secrets to Choosing the Best Drum Truck for Your Business Needs

-

Discover the Finest Forklift Drum Dumpers from China's Leading Manufacturing Facility

-

Innovative Uses for the Drum Hand Truck in Various Industries

-

7 Expert Tips for Choosing the Best Forklift Barrel Dumper for Your Warehouse

-

Understanding the Functionality of Barrel Lifters in Modern Industry

-

How to Choose the Right Drum Dolly for Your Business Needs